Embrace the power of RFID

Say goodbye to chaos and inefficiency and welcome a digital supply chain, which

ELIMINATES MISTAKES

ENSURES MATERIAL AVAILABILITY

AUTOMATES INVENTORY CONTROL

We eliminate everyday inefficiencies, empowering our customers to focus on their core business.

Read more about how to optimize your core processes with our RFID- and RTLS-systems.

Solutions that empower Digital Supply Chains

Welcome to a world, where every item is effortlessly traceable. By harnessing RFID and RTLS technologies we revolutionize the way companies monitor and locate their assets.

Our comprehensive Track-and-Trace platform helps digitize your supply chain, ensuring material availability, inventory visibility and delivery accuracy.

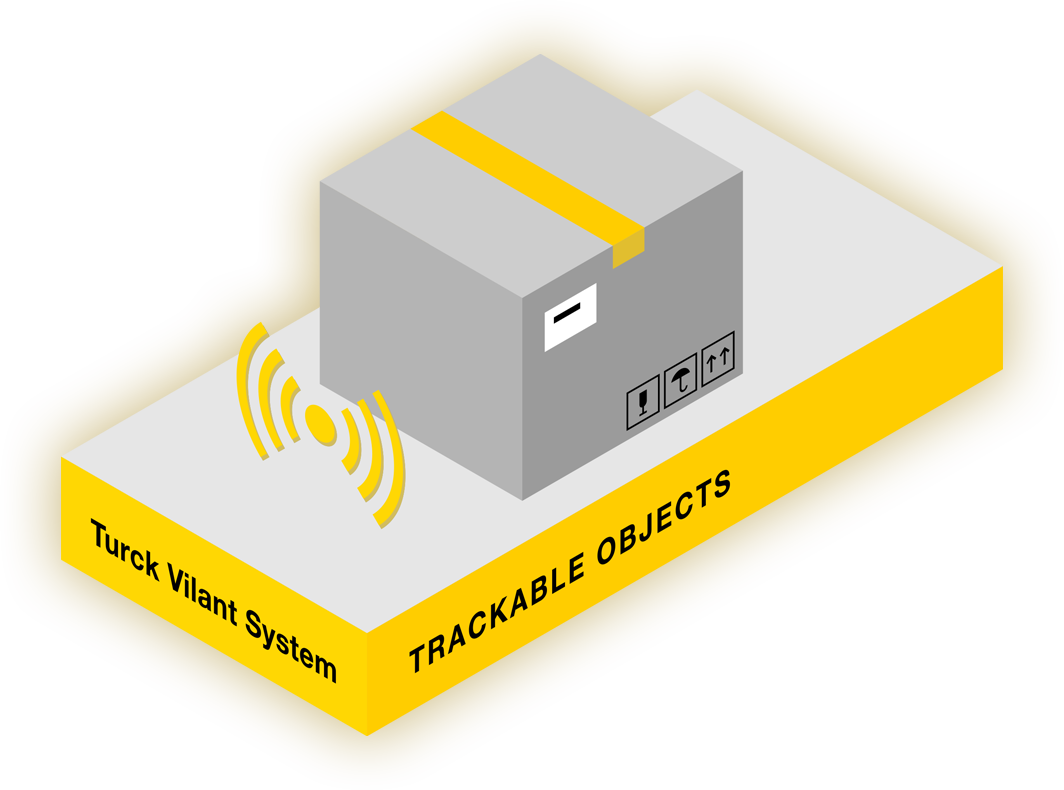

Digitizing your assets

RFID and RTLS technologies help enhance visibility cost-effectively. To digitize an object, all that is needed is to apply the correct tag.

A key service we offer is tag selection. Experience has taught us that the tag can make or break the system. The correct tag is crucial for a well-working and automated track-and-trace system.

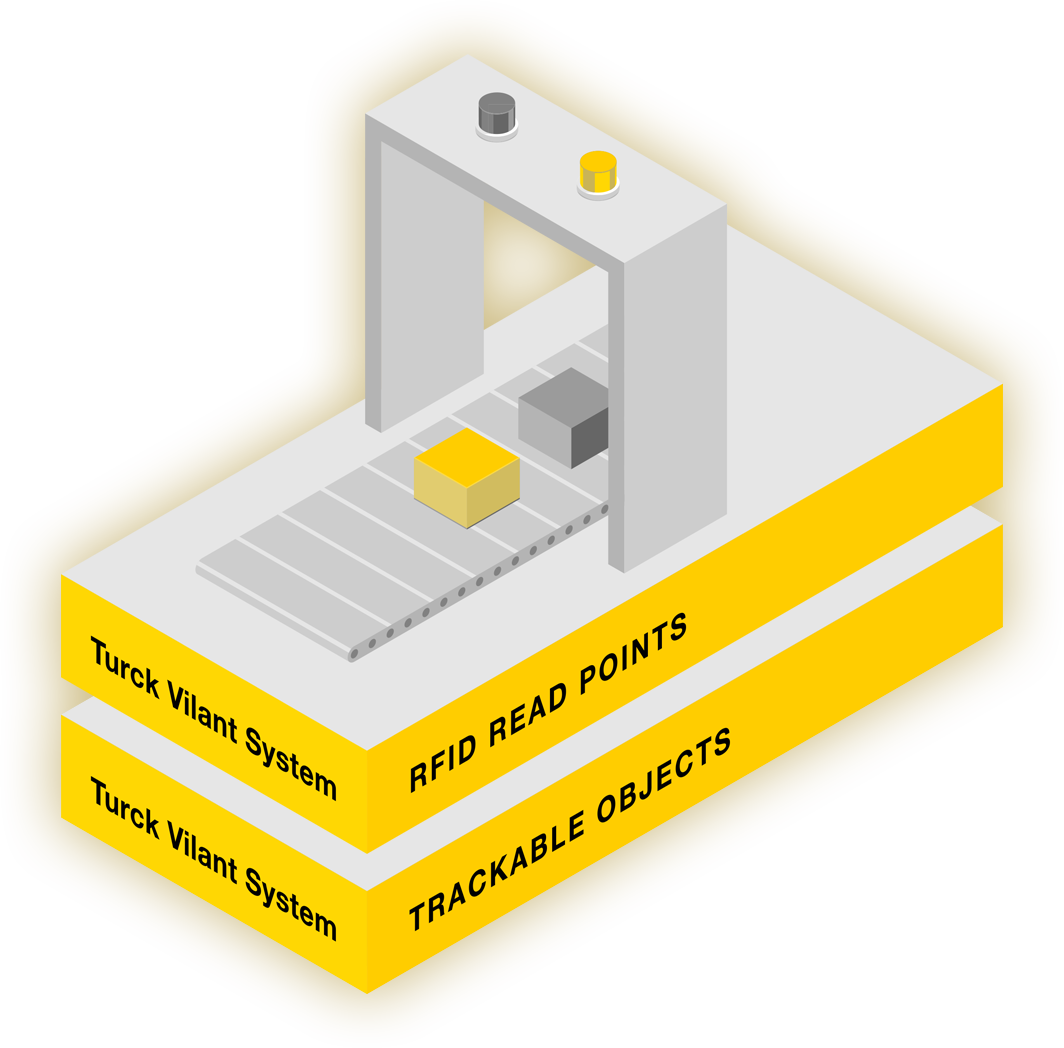

Monitoring actions and item whereabouts

Placing RFID read points at critical junctures in your supply chain safeguards data capture and provides data on user actions and item whereabouts.

Our track-and-trace solution builds upon a mixture of read points optimized for environments including forklift use, dock doors, conveyor lines and self-service.

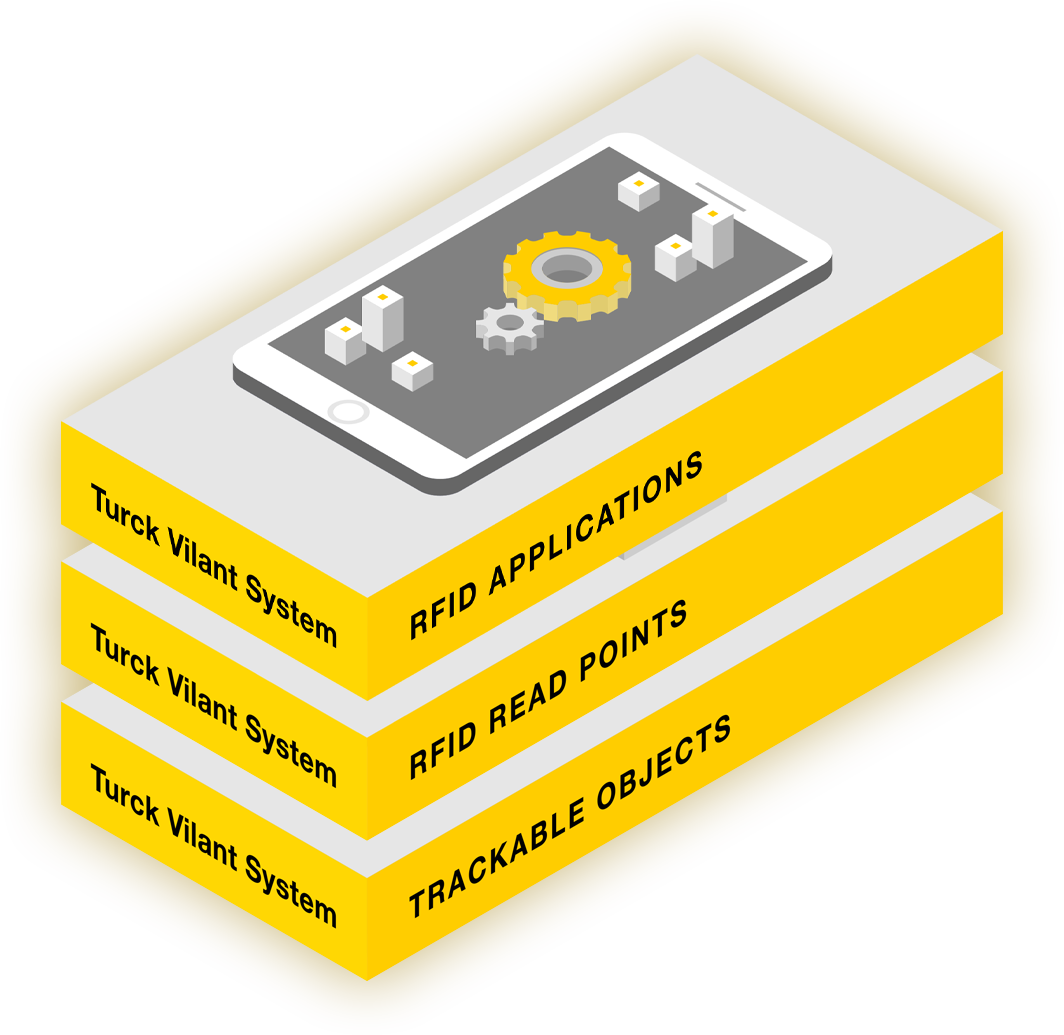

RFID Applications

By capturing data at key points, our customers gain insights into their processes and actionable information on their inventory levels and shipment accuracy. We have finetuned our applications in close collaboration with our customers to serve most industrial use cases.

Our RFID software kit comprises 30+ applications that run autonomously on RFID readers or, when operated by the user, on Windows and Android environments.

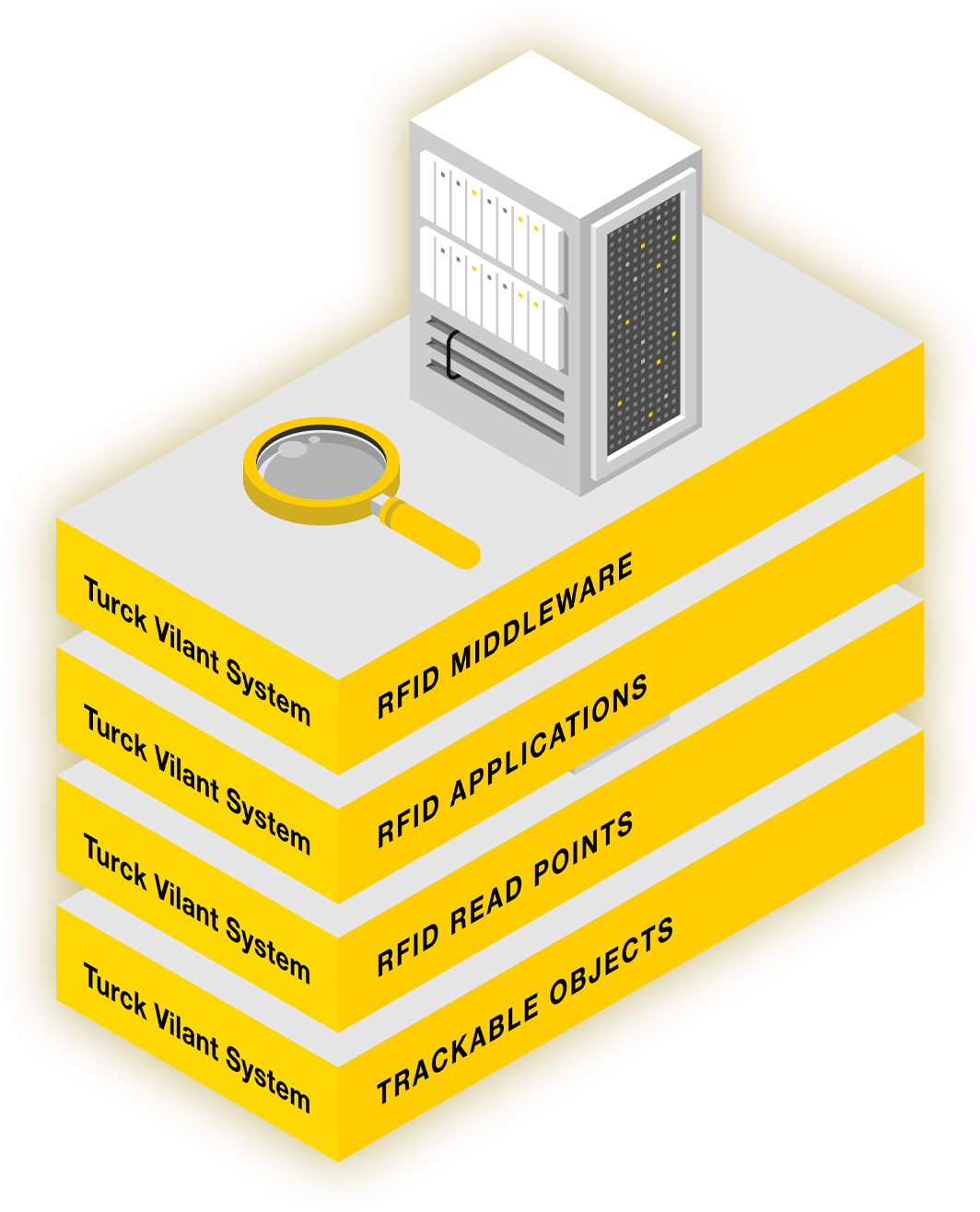

RFID middleware

Company business systems, such as ERP or WMS, keep track of material consumption, availability, and product data and help plan production and delivery. These systems rely on the user to input accurate and up-to-date information.

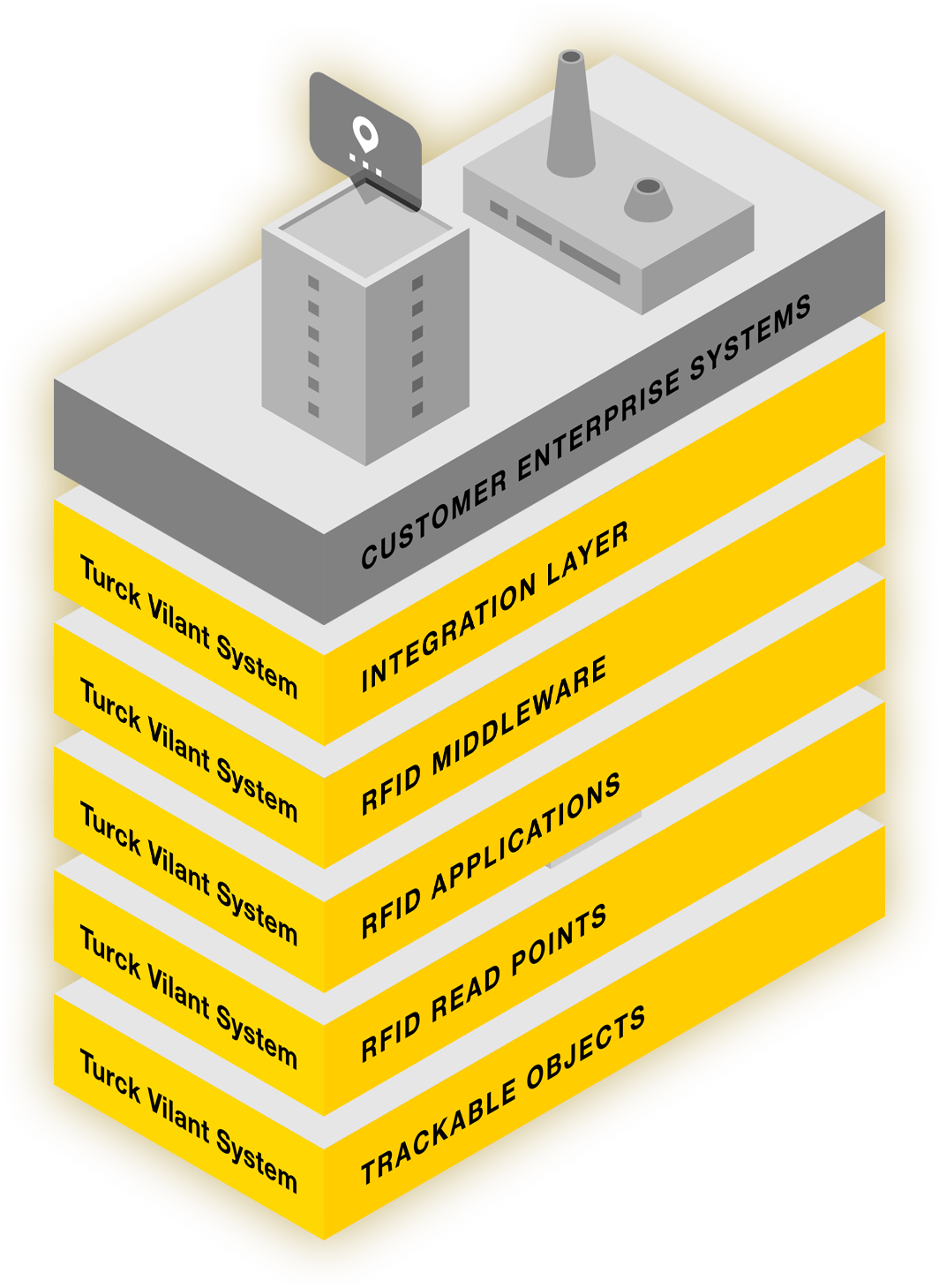

Our RFID middleware bridges the gap between RFID software and customer IT-systems. It has two pivotal roles: consolidating and recording all collected data and monitoring the operability of individual devices in the system, ensuring system health.

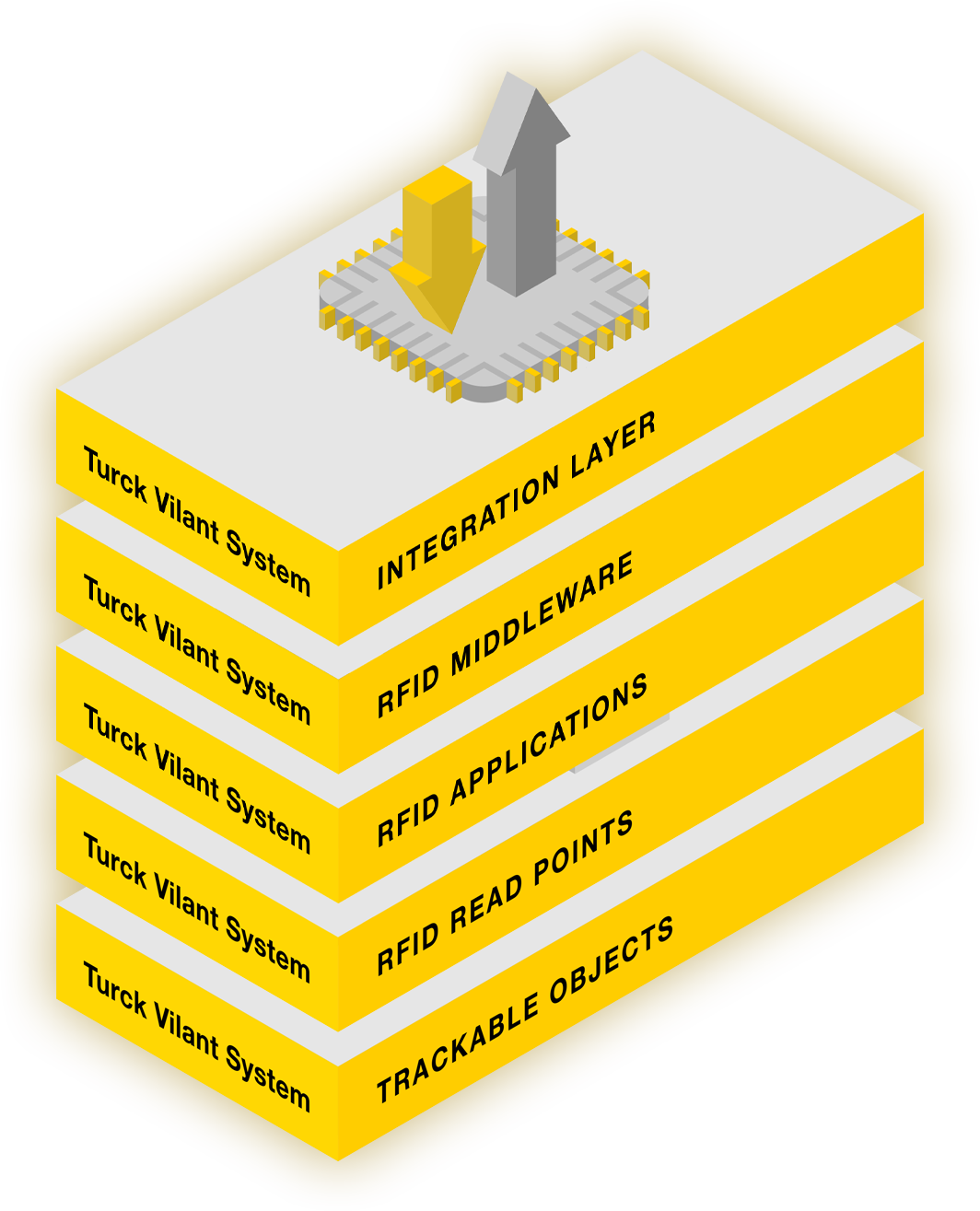

Seamless integration to customer Enterprise Systems

Customers across the globe need smooth data exchange across diverse environments and IT systems. Our traceability platform supports a variety of options for integrating RFID and RTLS technologies with different business IT systems.

Our software team has years of experience working with ERP such as SAP and WMS systems. Our ready interfaces and API result from close customer cooperation and meticulous recording of best practices.

Prosper through a Digital Supply Chain

As product lifecycles become shorter and the amount of SKUs grows, supply chains must evolve to be more efficient.

To remain profitable, our customers have rethought their supply chains to streamline processes, gain better visibility, and ensure product and material availability. In addition, many benefit from the automation offered by the technology, which saves person-years in labour and offers significant drops in claims costs.

Read more about our customer successes:

An intelligent RFID System tracks materials, inventory and, assets

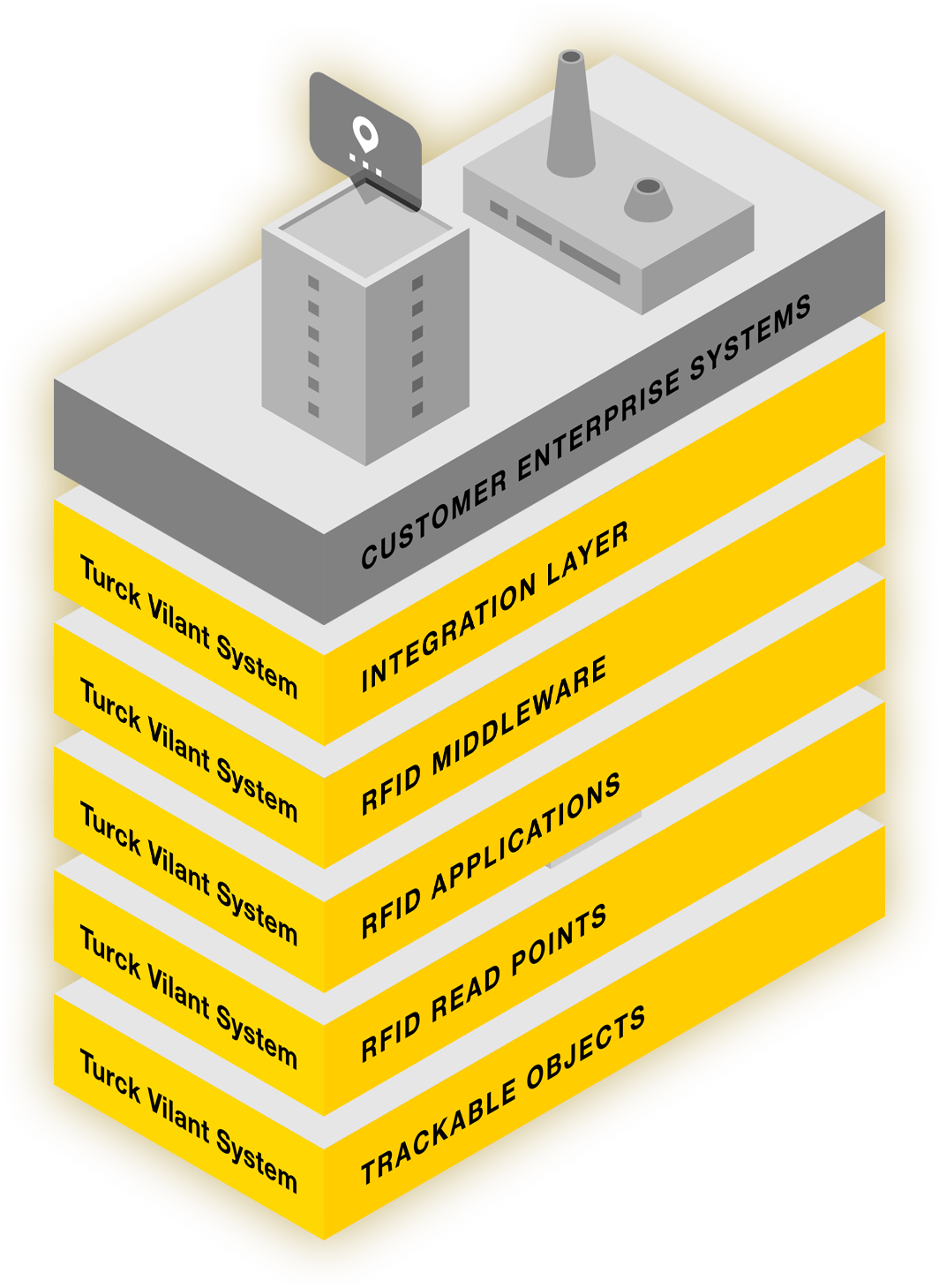

Our in-house developed track & trace platform comprises an intelligent RFID system. In addition, it expands to utilize active tracking elements, such as BLE (Bluetooth Low Energy), GPS, or other IoT equipment when needed.

RFID and IoT-based solutions bridge the gap between the physical and company IT worlds. For example, the company’s IT system cannot see what the operators in production or warehouses do. Thus, our IoT and RFID system acts as the bridge and verifies the use of correct materials and tools during production ramp-up.

Our solution gives unique identities to finished products or production batches, allowing the track and trace system automatically monitor their warehouse location, availability, and shipment status.

We equip dock doors, forklifts, mobile devices, and conveyor belts with RFID, sensors, and other IoT devices to help track individual products, boxes, roller cages, or pallets used for shipping.

The Turck Vilant Systems RFID system supports using RFID on forklifts, conveyor belts, mobile devices, and gates to ensure the picking, using, and shipping of correct items.

5 Reasons why Track & Trace

Time and Effort Wasted on Chasing Shipment Errors

An estimated 31% of shipments contain errors. Track & Trace solutions have been proved to drive delivery accuracy and cut the process time by up to 86%.

We solve everyday inefficiencies to allow our customers to focus on their core business.

From Primitive to Pioneering

When implemented in a production warehouse RFID eliminated wasted search time for materials, gaining real-time visibility to thousands of items. This revolutionized inventory management and production flow.

We solve everyday inefficiencies to allow our customers to focus on their core business.

Automatic Material Tracking Drives Efficiency

Material tagging helps with factory automation and plays a part in increasing the factory throughput with 60%.

We solve everyday inefficiencies to allow our customers to focus on their core business.

RFID Drives Rental Key-Drop Visibility

By tagging rental car keys, RFID ensures accurate, real-time visibility of returns as soon as keys hit the box. Simple for the user, smart for operations.

Questions on RFID?

Contact us with this form.

With more than 15 years of experience we are the company to kick start your RFID system project.

Don’t hesitate to leave your contact details below for our experts to contact you for more information on our Solutions and Refences.

You can also find the direct contact details of our Sales team. Find my local contact.